Infrared spectroscopy

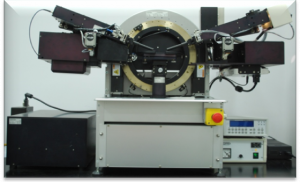

The Bomem DA8 is Fourier-transform spectrometer that allows for the measurements in the far-infrared frequency range (100-600 cm-1) at temperatures between 4 and 400 K, in the reflectivity and transmitance regimes, and with a maximal resolution of 0.02 cm-1. It is operating under the vacuum, having high resolution, high scanning stability and an access to several input-output ports for several different experiments. It has a vertical conventional Michelson interferometer with a patented dynamical alignment system keeping the exact alignment of the mirrors during each scan. As sources it can use a Hg lamp, a Globar (SiC) and a Quartz lamp. The beamsplitter is Hypersplitter and the detector is DTGS. The spectrometer is equipped with cryostat Janis STDA 100 (LN2 and a LHe, 4-400 K), which allows measurements in vacuum and variable temperatures. For data acquisition and processing, the DA8 uses the Bomem GRAMS software.

Bomem DA8.

The Thermo Nicolet systems allow for the measurements in mid-infrared range (400-5000 cm-1) in transmittance and absorbance regimes, in ambient conditions. They use KBr beamsplitter and DTGS detector, and the maximal spectral resolution is 0.125 cm-1 for Thermo Nicolet Nexus 470, and 0.4 cm-1 for Thermo Nicolet iS10. They are ideal for quick and easy spectral analysis and identification of materials. For the spectra analysis they are equipped with OMNIC Software Suite.

Thermo Nicolet Nexus 470.

Thermo Nicolet iS10.

Thin Film and Crystal Growth Laboratory

Thin Film and Crystal Growth Laboratory consists of several crystal growth techniques such as Czochralski, Bridgman or floating zone, thin film technology methods (thermal evaporation, spattering, laser ablation), sol-gel technology, spin-coating technique, sintering, etc. Here we will show only two crystal growth techniques.

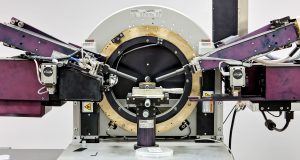

Crystal growth using floating zone technique: Four Mirror Lamp Image Furnace.

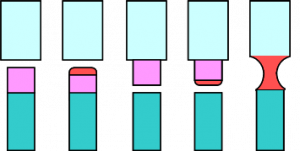

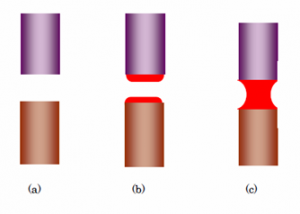

The floating zone technique is a powerful tool for the fabrication of high quality single crystals as well as for the purification of materials. A new four mirror optical floating zone furnace FZ-T-1000-H-HR-I-VPO-PC (Crystal System Co.) consists of four ellipsoidal mirrors made of Pyrex glass coated with highly reflective aluminum. The mirrors are air-cooled in order to prevent moisture condensation on the ellipsoidal surfaces. The principle of this technique is that radiation from the Halogen lamps is reflected and focused by the mirrors onto the bar sample to form a molten zone at the tip of the feed rod. Then the molten (floating) zone is translated along the sample length by moving the mirror stage with respect to the sample. The crystal is grown on the solidifying end of the floating zone. In addition, a rotation movement of the rod improves the microstructural homogeneity during directional solidification.

In the crucibleless floating zone technique the molten zone is kept together by capillary forces. The optical heating is the optimal way to bring a narrow zone of the sample to melting. In FZ-T-1000-H-HR-I-VPO-PC optical furnace the maximum operating temperature is 2200°C in atmosphere (air, nitrogen, oxygen, argon, etc) within the pressure range from 5x10-5 up to 10 bars. Crystals can be obtained up to 150 mm in length and 10 mm in diameter, with a growing rate of 0.05-27 mm/h and a 5-60 rpm rotating rate.

Four mirror optical furnace model FZ-T-1000-H-HR-I-VPO-PC (Crystal System Co.) with vertical molysili furnace model VF1800 (right).

Advantages of the four mirror floating zone furnace:

- Stable molten zone - Using high quality four glass mirrors and aluminum frame, a stable molten zone can be achieved;

- Small size - Mirror stage moving system can diminish the scale of the furnace, so that crystals as long as150 mm can be grown;

- Remote monitor and remote control system - Connect a PC to LAN system, monitoring and controlling of the furnace can be done from anywhere in the world;

- PC control - All the parameters for growing single crystals can be set and controlled by the personal computer;

- High quality glass mirror - Suitable for a long-term use, and optimal conditions are easily maintained. The surface is easy to clean, no damage occurs;

- Variety of halogen lamps - The most suitable lamp can be selected from various power lamps (150W, 300W, 500W, 1,000W and 1,500W lamp are available);

- Monitoring by the CCD camera - High quality color CCD camera and monitor can give real time control of the growth;

- Phase research by the slow cooling float zone method - Stable molten zone by the four mirror system can give the phase relation using the slow cooling float zone method.

|

The growth of incongruently melting or peritectic compounds |

Growth of congruently melting compounds

|

|

| 1) First stage: Set the solvent zone chip on the top of the seed rod. A small amount of starch paste can be used to fix it. The starch will be burnt off as the temperature increases, and a small amount of smoke will appear.

2) Second stage: Both the top of the solvent zone chip and the end of the feed rod are partially melted, and connected without rotation of either the upper or lower shafts. After connecting, the lamp power is slightly decreased and the upper shaft is retracted to separate the solvent zone. 3) Third stage: Both the end of the solvent zone chip and the top of the seed rod are partially melted, and brought into contact with rotation of both shafts. 4) Final stage: Adjust the lamp power to keep the molten zone stable and to melt a few millimeters of the top portion of the seed. After a few minutes, the crystal growth will begin. |

1) At the initial stage of the heating, both the feed and seed rod are set apart by a distance of a few mm;

2) As the heating progresses, both ends of the feed and seed rod will begin to melt; 3) At this stage, the upper feed rod is moved to downwards until it touches the seed rod. Finally, the length of the molten zone is adjusted so that its diameter is almost the same as that of the feed and seed rod. |

|

Advantages of Floating zone in comparison with the Czochralski method:

- High purity crystals can be grown without contamination from the crucible;

- Can be applied to grow oxide, metal and other materials;

- Can grow single crystals of incongruently melting materials;

- Low cost of the crystals growth;

- Can be applied in phase research by the slow cooling float zone method.

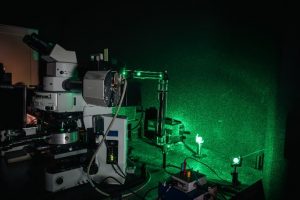

Spectroscopic ellipsometry

The GES5E-IRSE Spectroscopic Ellipsometer is a combined system consisting of: DUV-Visible-NIR Spectroscopic ellipsometer (SE) and Fourier Transform Infra-Red Spectroscopic Ellipsometer (FTIR-SE). The polarizer and analyzer arms of both ellipsometers are mounted on a high resolution goniometric bench, made of double hollow crown. Both these crowns are driven by computer controlled stepper motors. The incidence angle can vary from 7 to 90° in DUV-Visible-NIR range, and from 20 to 90° in MIR range, with a theoretical resolution of 0.0005°.

GES5E-IRSE Spectroscopic Ellipsometer.

The DUV-Visible-NIR Spectroscopic ellipsometer (SE) is working in a rotating polarizer configuration. It operates on the principle of mechanical modulation of the incidence light polarization by rotation of the polarizer at a constant angular frequency of 9 Hz. The analyzer remains in a fixed position, preparing the signal for the detector, insensitive to polarization. The precision of the ellipsometer for both weak and strong absorbing materials characterization is significantly enhanced with an automatically adjustable compensator. The light source is one 75 W Xe arc lamp, directly adapted to the polarizer arm. It emits a continuous spectrum of light, ranging from ultraviolet, trough visible to infrared (185-2000 nm). The light spot on the sample in parallel beam configuration is 1-10 mm2, depending on the aperture. There is also an additional miscrospot option for focusing the beam with a spot size of 365 x 270 μm, for an incidence angle of 75°. The light is introduced from the analyzer arm to the spectrometer using optical fiber making the light beam more stable. By combining the spectrometer with the photomultiplier tube (PMT) detector in UV-VIS range (190-900 nm), and InGaAs detector in NIR range (750-2000 nm), a high resolution spectrum is obtained by scanning the ellipsometric image at many discrete wavelengths. The spectrometer contains two dispersive elements (grating and prism) in collaboration with each other, separated by an intermediate fixed slit. The grating is blazed at optimum wavelength in order to obtain a maximum efficiency and the prism refracts the incoming wavelengths to act as a filter for higher order of diffraction produced by the grating.

The Fourier Transform Infra-Red Spectroscopic Ellipsometer (FTIR-SE) is a combination of a rotating analyzer configuration and a Fourier transform spectrometer. The basis of the FTIR spectrometer is a Michelson interferometer, which modulates each wavelength by a different frequency. The light leaving the Michelson interferometer enters the ellipsometer and successively passes the polarizer, the sample, the analyzer and finally hits the detector.

The light source for this IR ellipsometer is a silicon carbide (SiC) globar. Our system uses two different detectors: MCT in a range 580 cm-1 to 7000 cm-1, and DTGS in a range 385 cm-1 to 6500 cm-1. There is also an optional compensator in order to improve the accuracy of the measurements.

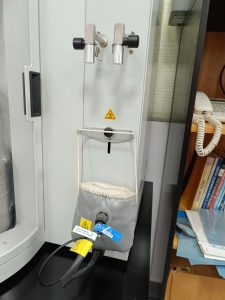

The ARS DX204 closed cycle low vibration cryostat with additional DMX-20 interface allows for the low temperature measurements up to 4.5 K. This cryostat is mounted on a specially designed SOPRA stage and SOPRA chamber with three possible angles of incidence (60°, 75°, 90°).

The spectroscopic ellipsometry measuresthe change in the polarization of light upon oblique light reflection on the surface of the sample to be studied. The incident light is linearly polarized, in general, it becomes elliptically polarized upon reflection. The polarization state of incidence light can be decomposed into s- and p- components, one perpendicular, and the other parallel to the plane of incidence. These two components reflect in a different manner, depending on the reflection properties of the surface. The ellipsometer measures ψ and Δ, which represent the ratio of reflection coefficients rp and rs, written as: r = rp/rs = tan(Ψ)eiΔ. Thus, tan(ψ) is the amplitude ratio upon reflection, and Δ is the phase difference.

ARS DX204 closed cycle cryostat with SOPRA cryostat chamber.

The spectroscopic ellipsometry can provide information about very thin layers, even down to a single atomic layer, or less. The measurements of the complex refractive index or dielectric function tensor give access to fundamental physical parameters that are related to a variety of sample properties, that include morphology, crystal quality, chemical composition, or electrical conductivity. It is commonly used to characterize single layer thin films or complex multilayer stacks ranging from a few parts of nanometers to several micrometers with an excellent accuracy.

Porosimetry

Thermo Fisher Scientific SURFER ANALIZER 11510300

PC-controlled gas adsorption analyzer, representing the pinnacle of analytical instrumentation available today. The SURFER system operates on the principle of static volumetric physical and chemical gas adsorption under precisely controlled temperature and pressure conditions, offering comprehensive insight into the microstructural properties of solids and powders. To ensure optimal performance, the SURFER unit must be coupled with appropriate sample preparation equipment.

The SURFER unit is configurable to suit various experimental setups, offering versatility in characterizing materials across a spectrum of disciplines. Key physical properties determined by the SURFER analyzer include specific surface area, pore size distribution, total pore volume, and exposed surface area, facilitating detailed analysis of catalysts, polymers, engineering materials, adsorbents, minerals, and powders.

Surfer Analytical Unit.

Built-in Degasser Unit.

Operation Overview

Fundamentally, the SURFER analyzer characterizes solids via physisorption measurements. Gas, typically nitrogen, is accurately dosed onto a sample at liquid nitrogen temperatures. The subsequent interaction between the gas and solid is monitored by observing the resulting absolute pressure within the system. This process enables a thorough and automated determination of the chemical and physical properties of solids.

Instrument Components and Functionality

The SURFER analyzer comprises two primary units: the analytical unit and the degasser unit. The analytical unit houses pneumatic lines, sample holders, liquid nitrogen storage, electromechanical and pneumatic components, and vacuum pumps. Meanwhile, the degasser unit facilitates sample degassing prior to analysis, with options for both built-in and external configurations. The built-in degasser unit is fully controlled via the SURFER Acquisition software, while the external unit can be manually programmed or controlled through the software.

Measurement Methods and Capabilities

The SURFER gas adsorption analyzer offers advanced automation, ensuring optimized analytical parameters throughout the measurement process and minimizing operator intervention. Its versatility and accuracy make it an indispensable tool for characterizing solids and powders across various industries. The system's ability to provide reliable, fast, and automated analysis, coupled with its high resolution, makes it ideal for research and industrial applications.